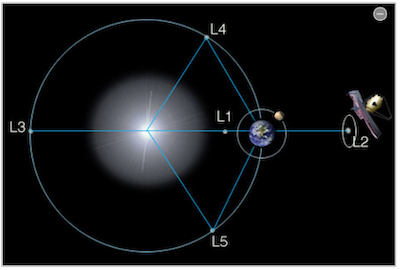

Lagrange Point 2 (L2) is one of the most scientifically significant places in the solar system.

Diagram of Lagrange Points

https://webb.nasa.gov/content/about/orbit.html 04/14/2024

Located in the Earth’s shadow moving away from the sun, it’s the point where their combined gravitational pull balances the centrifugal force of an object in orbit. In other words, L2’s inherent stability makes it the ideal location for an advanced telescope to study the distant stars and galaxies of deep space.

It's also far. At nearly one million miles away, L2 is more than four times as far as the moon and far too distant for human crews to install or service a telescope.

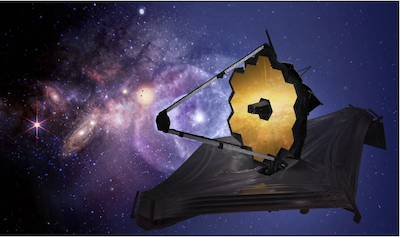

So, when NASA, the European Space Agency, and the Canadian Space Agency teamed up to create the 14,000 lb. NASA’s James Webb Space Telescope (Webb), whose thousands of components would be manufactured around the world, shipped to Northrop Grumman in Redondo Beach, CA, for assembly, and then off to French Guiana for launch, one of their mandates was Zero Failure.

The James Webb Space Telescope

https://science.nasa.gov/mission/webb/ 04/14/2024

And Zero Failure requires testing. Methodical, documented, systematic, and repeated testing of every single component and assembly by a small army of engineers.

One of these test engineers is Northrop Grumman’s Riley Benson, who earned an Aerospace, Aeronautical and Astronautical Engineering degree at Rensselaer Polytechnic Institute (RPI) and is currently pursuing a master’s degree at Rensselaer at Work. “Every component had to pass tests and every test had to be documented and reviewed from anywhere by four to twelve engineers,” Riley explained. “Components on the Critical Path especially were subjected to dozens of tests because there’s no way to fix things that could go wrong.”

From its launch on Christmas Day 2021, to entering service six months later, thousands of tests were run and passed. “Just putting together the 18 hexagonal mirrors for the telescope array took 10 days and then came the fine-tuning,” Riley noted. “It’s over six times larger than The Hubble Space Telescope and the sunshield is about as big as a tennis court.”

And then the images began to pour in. Gorgeous, stunning images that will keep a generation of scientists busy for the entire lifespan of the Webb, which is planned for 10 years but expected to last twenty.

Riley, meanwhile, is also working on his next 10-20 years by finishing up his master’s degree in systems engineering and technology management at Rensselaer at Work. “I got to work on one of the most technologically challenging projects in history,” he noted, “and now it’s time to prepare for the next one.”

Riley Benson`24 with his subject at work

Careerwise, his choices were to become a Master Engineer or to enter technology management, so Riley chose the latter. As part of his coursework, he’s learning to optimize complex systems — Riley practices with video games because his work systems are already optimized — as well as managing up and down for technologically-advanced organizations. Webb, which is now sharing L2 with two other satellites, will need to be replaced before long.

“A number of my co-workers are also in graduate programs,” he said, “and it’s clear to me that Rensselaer at Work’s project-based approach works better than traditional programs. I share what I’m working on with my instructors and, by the next day, I’m already applying what they’re teaching me. They get really energized when I tell them about working on Webb.”

“I also appreciate the scheduling flexibility.” Riley noted. “I’m on West Coast time and Northrop Grumman is very supportive, so it’s never been a problem. I tend to be the one who steps in when someone on my team is on vacation, so it’s great that my instructors are just as supportive.”

In the near future, Riley is set to graduate this year as part of Rensselaer’s 200th anniversary as America’s first technical research institute. Beyond that, the sky, as they say, is the limit.